The polypropylene cubes have a density of 0.946, a unique characteristic that sets them apart from other materials. Their exceptional strength, flexibility, and resistance to chemicals make them a versatile choice for a wide range of applications. This article delves into the properties, measurement, and impact of density on the performance of polypropylene cubes, exploring their diverse applications and comparing them to alternative materials.

Polypropylene cubes are composed of a thermoplastic polymer known for its lightweight and durable nature. Their density of 0.946 g/cm³ contributes to their buoyancy, making them suitable for applications in packaging, construction, and medical fields. The manufacturing process involves molding techniques that control the density of the cubes, ensuring consistent quality and performance.

Polypropylene Properties

Polypropylene is a versatile thermoplastic polymer with unique characteristics that make it a valuable material in various industries. It exhibits exceptional strength, flexibility, and resistance to chemicals, making it suitable for a wide range of applications.

Strength and Flexibility

Polypropylene is known for its high tensile strength and impact resistance. Its strong molecular structure enables it to withstand significant forces without breaking or deforming. Additionally, its flexibility allows it to bend and conform to different shapes without cracking, making it ideal for applications requiring both strength and flexibility.

Chemical Resistance

Polypropylene is highly resistant to a wide range of chemicals, including acids, bases, and solvents. This property makes it suitable for use in harsh environments where exposure to chemicals is unavoidable. It is also resistant to moisture and UV radiation, ensuring long-term durability.

Applications

Due to its exceptional properties, polypropylene is used in a diverse range of industries, including packaging, construction, automotive, and medical. Its strength and flexibility make it suitable for applications such as packaging containers, pipes, and automotive parts. Its chemical resistance makes it ideal for use in chemical processing equipment and medical devices.

Density Measurement

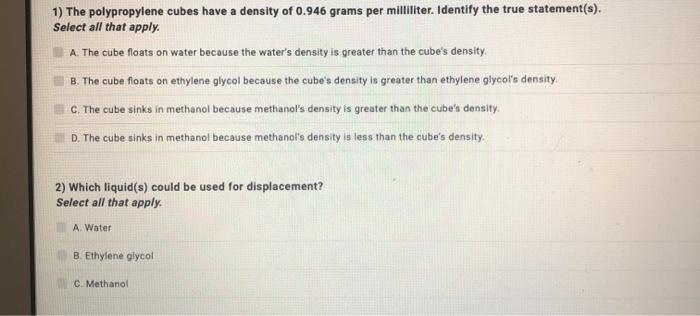

Density Definition and Significance

Density is a measure of the mass of a substance per unit volume. It is an important property for materials, as it influences their performance and behavior in various applications. For polypropylene cubes, density plays a crucial role in determining their buoyancy, strength, and thermal insulation properties.

Density Measurement Techniques

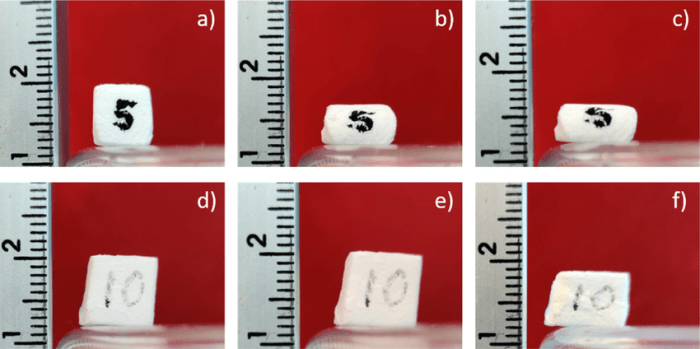

There are several methods used to measure the density of polypropylene cubes. One common technique is the Archimedes’ principle method, which involves immersing the cube in a fluid of known density and measuring the buoyant force acting on it. Other methods include the pycnometer method, which measures the volume of a known mass of the cube, and the gravimetric method, which involves weighing the cube in air and in a fluid.

Examples of Density Measurement Techniques

- Archimedes’ principle method: Measuring the buoyant force of the cube in water or another fluid of known density.

- Pycnometer method: Measuring the volume of a known mass of the cube using a pycnometer.

- Gravimetric method: Weighing the cube in air and in a fluid to determine its volume and density.

Impact of Density on Applications: The Polypropylene Cubes Have A Density Of 0.946

Buoyancy

The density of polypropylene cubes influences their buoyancy. Cubes with lower density float more easily than those with higher density. This property is important for applications where buoyancy is a factor, such as in marine floats and packaging for lightweight products.

Strength

Density is also related to the strength of polypropylene cubes. In general, cubes with higher density tend to be stronger and more rigid. This is because higher density indicates a more compact molecular structure, resulting in increased resistance to deformation and breakage.

Thermal Insulation

Polypropylene cubes with lower density provide better thermal insulation than those with higher density. This is because lower density indicates a higher concentration of air pockets within the material, which act as barriers to heat transfer.

Application Considerations

When selecting polypropylene cubes for specific applications, it is important to consider the impact of density on their performance. For example, applications requiring high buoyancy may require cubes with lower density, while applications requiring high strength or thermal insulation may benefit from cubes with higher density.

Applications of Polypropylene Cubes

Packaging

Polypropylene cubes are widely used in packaging due to their strength, flexibility, and chemical resistance. They are commonly used for packaging food, beverages, and other products that require protection from moisture, chemicals, and physical damage.

Construction

In the construction industry, polypropylene cubes are used as lightweight and durable building materials. They are often used as void fillers in concrete structures, providing insulation and reducing the overall weight of the building.

Medical

Polypropylene cubes are also used in medical applications due to their biocompatibility and chemical resistance. They are used in the production of medical devices, such as surgical implants and drug delivery systems.

Influence of Density, The polypropylene cubes have a density of 0.946

The density of polypropylene cubes plays a significant role in their suitability for different applications. For example, in packaging, cubes with lower density are preferred for lightweight products, while cubes with higher density are used for heavier products requiring increased strength.

Manufacturing Process

Raw Materials

Polypropylene cubes are manufactured using polypropylene resin, which is a thermoplastic polymer derived from propylene gas. The resin is typically supplied in the form of pellets or granules.

Molding Techniques

The most common method of manufacturing polypropylene cubes is injection molding. In this process, molten polypropylene resin is injected into a mold cavity, where it cools and solidifies into the desired shape. Other molding techniques, such as compression molding and rotational molding, can also be used.

Quality Control

To ensure the quality and consistency of polypropylene cubes, manufacturers implement strict quality control measures throughout the manufacturing process. These measures include testing the raw materials, monitoring the molding process, and inspecting the finished products for defects.

Density Control

The density of polypropylene cubes is controlled during the manufacturing process by carefully adjusting the molding parameters, such as the temperature and pressure. By controlling these parameters, manufacturers can achieve the desired density for the specific application.

Comparison with Other Materials

Polyethylene

Polyethylene is another thermoplastic polymer that is similar to polypropylene in many respects. However, polyethylene has a lower density and is more flexible than polypropylene. This makes it suitable for applications where flexibility and low weight are important, such as in plastic bags and films.

Polystyrene

Polystyrene is a lightweight and inexpensive plastic that is commonly used for packaging and disposable products. It has a lower density and strength than polypropylene, making it less suitable for applications requiring high strength or durability.

Advantages of Polypropylene Cubes

Compared to polyethylene and polystyrene, polypropylene cubes offer several advantages, including:

- Higher strength and rigidity

- Better chemical resistance

- Improved thermal insulation

Disadvantages of Polypropylene Cubes

One disadvantage of polypropylene cubes is that they are more expensive than polyethylene and polystyrene. Additionally, polypropylene is not as biodegradable as some other plastics, which can be a concern for environmental sustainability.

FAQ Resource

What is the significance of the density of polypropylene cubes?

The density of polypropylene cubes, 0.946 g/cm³, plays a crucial role in determining their buoyancy, strength, and thermal insulation properties, influencing their suitability for various applications.

How is the density of polypropylene cubes controlled during manufacturing?

The density of polypropylene cubes is controlled through the molding techniques employed during the manufacturing process. These techniques ensure consistent density throughout the cubes, meeting specific performance requirements.

What are the advantages of using polypropylene cubes over other materials?

Polypropylene cubes offer advantages such as high strength-to-weight ratio, excellent chemical resistance, and low thermal conductivity, making them a preferred choice for applications where these properties are critical.