Capillary tube metering devices are commonly used today in a wide range of industries and applications, from medical and pharmaceutical to manufacturing and automotive. These devices, based on the principles of surface tension and capillary action, offer precise and reliable flow control of liquids and gases.

The history of capillary tube metering devices dates back to the early 19th century, and they have since undergone significant advancements and innovations. This article delves into the principles of operation, design, and construction of capillary tube metering devices, exploring their diverse applications, performance characteristics, and future trends.

Introduction

Capillary tube metering devices are widely used today for precise fluid control in various industries. These devices utilize the principles of capillary action to regulate the flow of fluids through narrow channels. The concept behind capillary tube metering has been known for centuries, but its practical application in metering devices has evolved significantly over time.

Principles of Operation

Capillary tube metering devices operate based on the principles of surface tension and capillary action. Surface tension refers to the tendency of a liquid’s surface to minimize its area, while capillary action describes the ability of a liquid to rise in a narrow tube against gravity.

When a capillary tube is inserted into a liquid, the liquid rises within the tube due to the combined effects of surface tension and capillary action. The height to which the liquid rises is determined by the tube’s diameter, the liquid’s surface tension, and the liquid’s density.

Design and Construction

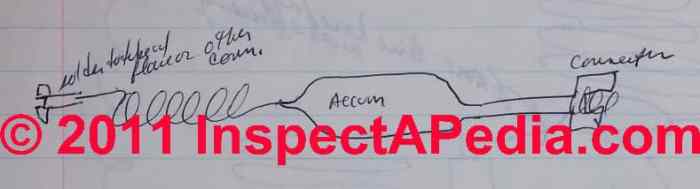

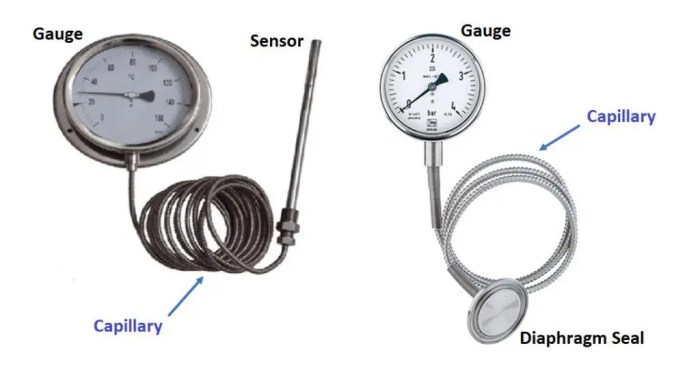

Capillary tube metering devices typically consist of a capillary tube, a reservoir, and a flow restrictor. The capillary tube is a narrow, cylindrical tube with a precisely controlled diameter. The reservoir holds the liquid to be metered, and the flow restrictor regulates the flow rate through the capillary tube.

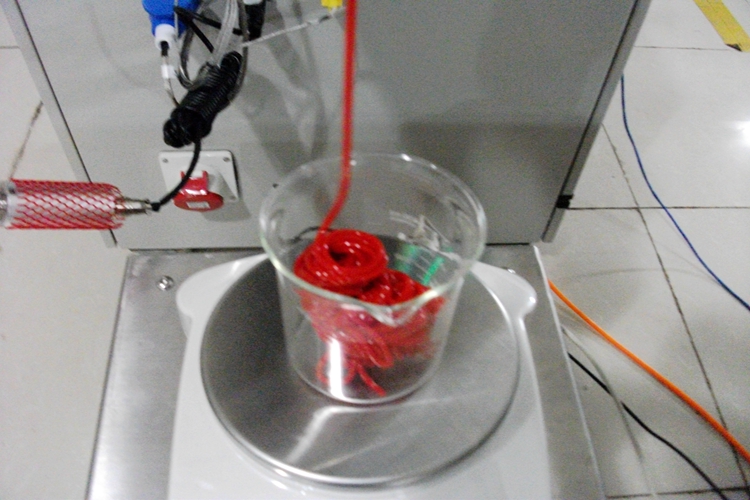

The materials used in the construction of capillary tube metering devices vary depending on the application and the properties of the fluid being metered. Common materials include glass, stainless steel, and polymers.

Applications

Capillary tube metering devices are commonly used in industries such as pharmaceutical, chemical, and food processing. They are employed in a wide range of applications, including drug delivery, chemical analysis, and fluid dispensing. Capillary tube metering devices offer advantages such as high precision, low cost, and simplicity of design, making them suitable for a variety of metering tasks.

Performance and Calibration: Capillary Tube Metering Devices Are Commonly Used Today In

The performance of capillary tube metering devices is influenced by factors such as the tube’s diameter, the liquid’s properties, and the operating conditions. To ensure accuracy and precision, capillary tube metering devices require calibration. Calibration involves adjusting the flow restrictor to achieve the desired flow rate.

Calibration methods vary depending on the specific device and application.

Advancements and Future Trends

Recent advancements in capillary tube metering technology include the development of microfluidic capillary tubes and the integration of sensors into the devices. Microfluidic capillary tubes allow for precise control of fluid flow at the microscale, opening up new possibilities for applications in microfluidics and lab-on-a-chip devices.

The integration of sensors into capillary tube metering devices enables real-time monitoring and control of the flow rate, enhancing the accuracy and reliability of these devices.

User Queries

What are the advantages of using capillary tube metering devices?

Capillary tube metering devices offer several advantages, including high precision and accuracy, wide flow rate range, low pressure drop, and the ability to handle small volumes of fluids.

How are capillary tube metering devices calibrated?

Calibration of capillary tube metering devices involves comparing the actual flow rate with the desired flow rate and adjusting the device accordingly. This can be done using a variety of methods, such as gravimetric or volumetric measurements.

What are the limitations of capillary tube metering devices?

Capillary tube metering devices have certain limitations, including the potential for clogging, sensitivity to temperature changes, and the need for precise manufacturing tolerances.